LGP 30

The 1st-generation dataprocessing system LGP-30 was developed in the United States by Librascope and General-Precision in the mid-1950s. About 40 such machines were built under a license agreement by Schoppe & Faeser in Germany. The LGP-30 was intended as a scientific computer system and was superseded by the LGP-21 in 1962.Programs and data are stored on 1" paper tape which are fed to a high-speed punch/reader. Manual input and output is performed by a so-called "Flexowriter" made by Friden. This device is basically an electric typewriter with a paper tape attachment.

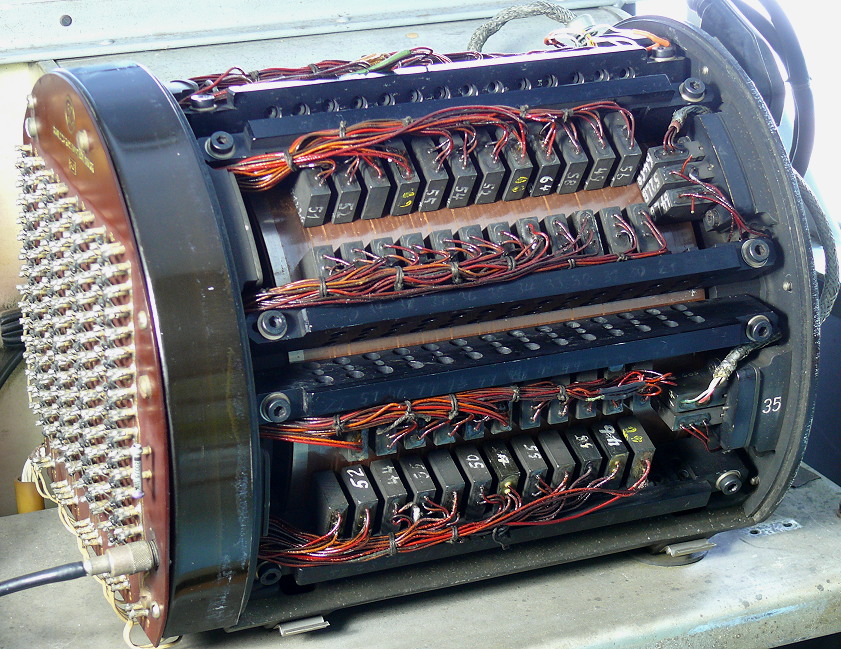

LGP-30 vacuum tube based computer - prior to restauration

Unfortunately, our machine is missing the special interconnect cables

for the high-speed paper tape system and the Flexowriter. Therefore we

are looking desperately for the required special connectors .

Apart from this, the machine is in rather good shape. First

of all the side panels have to be repainted and all the mechanic parts

have to be brought back to working condition. After that the electronics

can be debugged - a true adventure, digging deep into vacuum tube based

digital electronics.

Front View without casing

enlarge picture

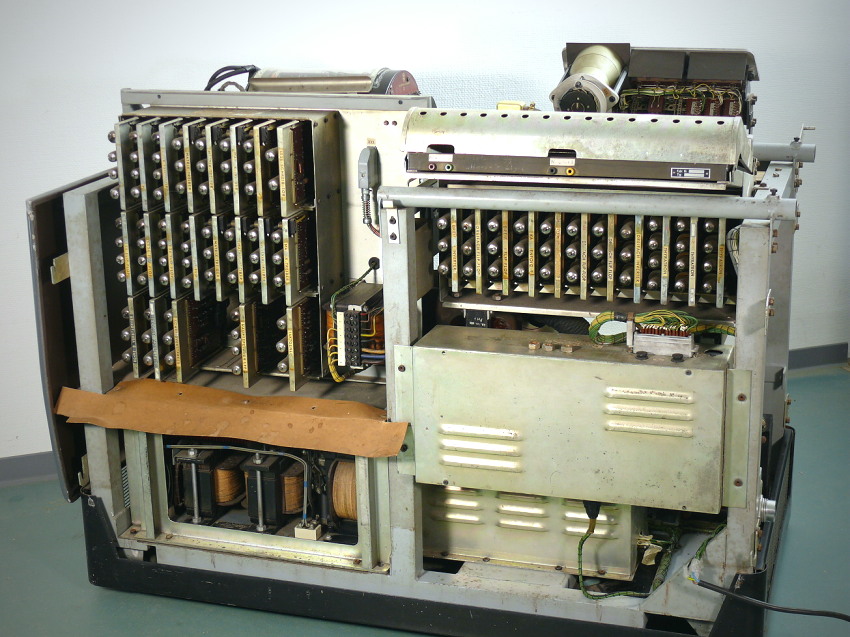

Backside without casing

enlarge pictureThe technical data is rather interesting: The magnetic drum rotates at

3600 RPM, the distance between two adjacent tracks is 2mm, a single track

has a width of 1mm and the spacing between read/write heads and the

drum surface is 25 um! The memory capacity is pretty large for its time

at 4,096 words of 32 bits each. The basic clock frequency is 120 kHz and

the access time is between 2 ms and 15 ms. A single addition takes

0.23 ms while a multiplication requires 15 ms (without the necessary

access times to the drum).

All in all, there are 113 long-life vacuum tubes and 1450 Germanium

diodes packaged in 34 modules (12 different module types).

Peripherals:

The paper tape reads is capable of reading 200 characters/s, the high-speed

punch can punch at 50 characters/s while the Flexowriter is capable of

printing 10 characters/s.

The processing unit (without peripherals) weights 350 kg.

Some historical data regarding our machine: Its whereabouts prior to 1962

are unknown. It was then used from 1962 until 1980 at a land surveying

office for various purposes including the generation of control paper

tapes for a ZUSE Graphomat Z64 plotter, recalculation of historic

triangulation nets, affine transformations, Helmert-transformations,

basic tasks for land surveying etc.

Those tasks were quite demanding and even a rather simple fit through

three points determined by triangulation took about 3 to 4 minutes of

computer time.

Now the restoration of this vaccum tube based computer started. The biggest

problem is the magnetic drum memory. Currently four options are under

consideration:

1. Applying a new magnetic coating to the damaged drum. This approach would

be ideal but also the most complex solution.

2. Simulating the complete drum assembly by a modern microcontroller.

Attaching this to the vacuum tube electronics would be feasible by means of

level shifters (0V and -20V are required for operation).

3. A discrete approach emplying RAMs, EPROMs, operational amplifiers and lots

of glue logic. This does not have any advantages over approach 2.

4. Replacing the rotating drum by a fixed assembly holding magnetic

read/write heads, one for each head of the drum. This approach has been

abandoned due to its complexity.

Compared with the complexity of emulating the drum assembly, the missing

cables are only a minor problem. Fortunately four experts will support the

restoration effort. We would especially like to thank Mr. Klemens Krause

Computermuseum-Stuttgart.